Blog by Alan Pickering.

Surely Multi-Stack and Multi-Radius bending machines are the same?

A few customers have fallen into this trap with catastrophic outcomes.

Some basics are that all multi-radius tube bending machines are multi-stack by default.

So what is the difference and why does it matter ?

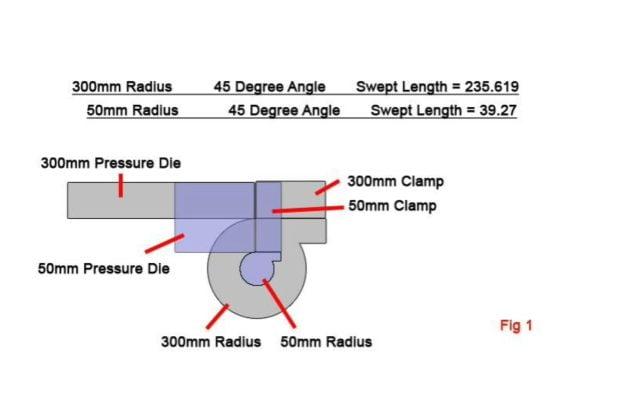

If you just have a multi-stack machine you can make parts that have Compound Tooling, such as for making an Engine Exhaust Manifold, where there is no change in bend radius, just small straights that require you to pull a bend while clamping on the previous bend.

In this scenario you would have a matching number of pressure dies that need stacking up.

If you have a part made up of different bend radii, then the potential problems arise.

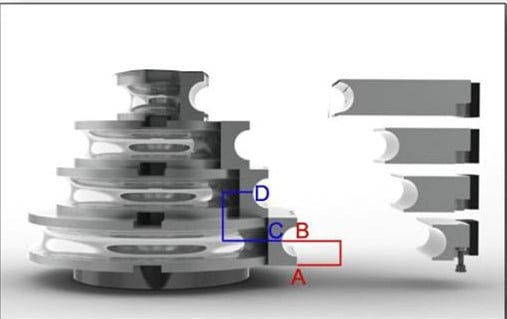

Difference image without lines.

Metaphorically, imagine a four-lane running track, over a full lap an athlete running on the inside lane has less distance to travel than the athlete in the outside lane, hence they have staggered start lines.

If they did not the athlete on the inside of the bend, running around the smaller radius, would come on the next straight much further ahead than the athlete on the outside.

The only way they could be even on the straight after the 180 degree bend is if the athlete on the outside ran much faster than the one on the inside.

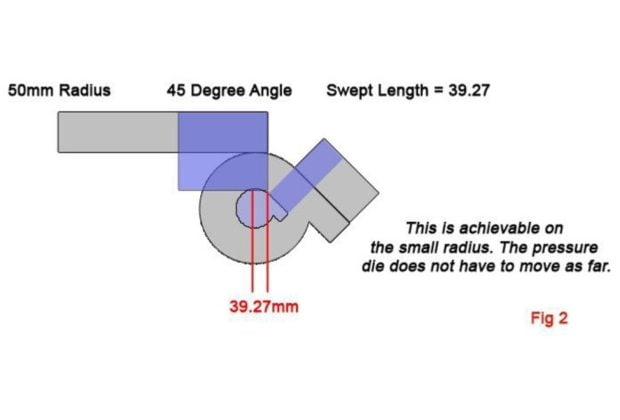

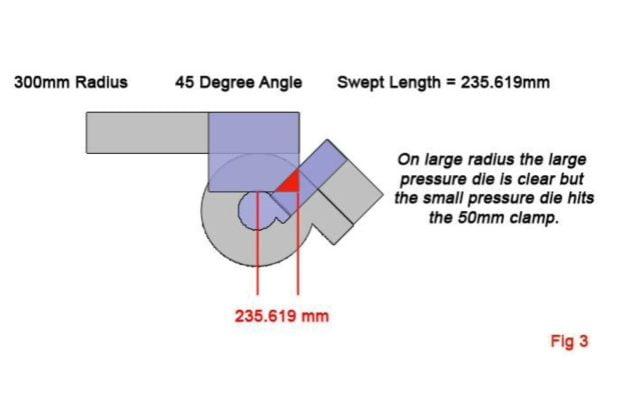

In terms of Tube Bending the images below pictorially show you issue from Fig.1 to Fig. 3

To be able to get around this issue, you need a pressure die that goes up and down. So that it can accurately track each former independently, with the relevant negative/positive push.

What happens if you find yourself in this scenario with a multi-stack machine ?

The only real way around this has a potentially serious outcome, and is definitely a compromise.

What you would have to do is set the follower to track the smallest radius only, which would mean that when bending on the largest radius you would have to be dragging significantly causing excessive wall thinning.

For the last 20 years Unison Ltd have only been making Multi-Radius machines, which sometimes commercially puts us at a disadvantage, but some things are not worth compromising.

Got a question for our expert team? Contact us now – sales@unisonltd.com.