Expert blog by our Managing Director Alan Pickering.

A Powered Follower or Pressure Die Boost is used to push material into the outside of the bend.

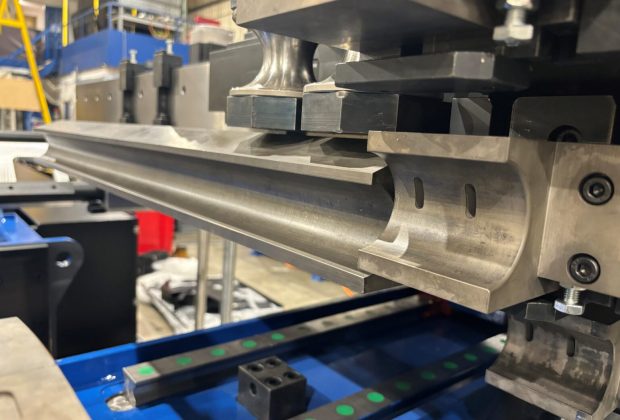

Powered Follower

A powered follower in a Unison tooling set-up

Why is it needed?

If you consider the centre of the tube as you look down the length of the machine as the neutral axis then, as you pull the bend, you can see that the outside of the bend is being stretched and the inside of the bend is being compressed.

On some larger Radii and with material that is happy to stretch with good elongation properties it may not be necessary to have a Powered Follower, however this is unusual and will cause excessive wall thinning throughout the bend.

The Powered Follower is in effect gripping the straight that is going to become part of the bend and the straight that follows the bend.

And if it has a setting that works on a ratio of greater than 1:1 it will be trying to steal material from the straight after the bend and push material into the bend area, in turn reducing wall thinning.

Exotic materials such as Titanium have a low elongation properties, and the radius that needs to be bent is tight, making it mathematically impossible to bend.

For example, if you have to achieve a Bend Radius of 1D then you need 50% more material on the outside of the bend compared to the Neutral Axis, if you only have an elongation of 25% it is clear to see this can’t work without stealing material from the subsequent straight, so pushing material into the bend is critical.

This strain of stealing material from the subsequent straight can quite often mean that only single bends can be made in the aerospace sector, allowing the end of the tube to teapot

To answer this question properly you need to consider the inside of the bend. Don’t forget this material is in compression, trying to thicken up along its length by the same factor as the outside of the bend.

For example, if you are bending at 1D then the material on the inside of the bend has to thicken by 50%. Often the material such as Titanium does not want to do this, and pushes material along its length adding to the teapot effect.

So in general, yes wall thinning is more of a problem than wall thickening, tackling this can often take priority.

Sometimes with rigid material such as Titanium pushing on the outside of the bend can prevent the material on the inside of the bend pushing back causing wrinkles.

More advanced control systems such as Unibend allow you to profile the Push/Pull throughout the bend, allowing you to find the balance, perhaps pushing initially and then pulling towards the end of the bend.

Check out all of our tooling options by contacting Luke Gibson – lukeg@unisonltd.com

Got a question for our expert team? Get in touch – sales@unisonltd.com