Blog by our tooling expert Luke Gibson.

Tube bending is a critical process in many industries, from automotive and aerospace to HVAC and furniture manufacturing.

The quality of a bend depends largely on the tooling used. This blog post will delve into the world of tube bending tooling, discussing the two most common types of bend dies and their applications.

A bend die, also known as a former, rad, or bending die, to name a few, is the primary tool used in the tube bending process. It is a shaped tool that guides the tube to bend in a specific radius and direction.

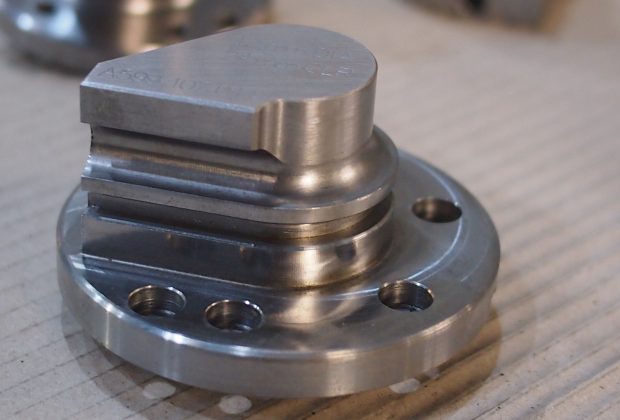

Flanged-based bend dies, also known as flange-mounted bend dies, are typically used for the tougher tube bending applications.

The die is mounted on a flange that is attached to the bending machine.

This type of mounting provides a secure and stable platform for the bend die, which can help improve the accuracy and consistency of the bends.

Flanged-based bend dies are often used when bending heavy-duty materials or when performing complex bends with a tight radius.

The flange provides additional support and stability, which can help prevent the tube/ tool from slipping or moving during the bending process.

Flanged-based bend dies, also known as flange-mounted bend dies, are typically used for the tougher tube bending applications.

The die is mounted on a flange that is attached to the bending machine. This type of mounting provides a secure and stable platform for the bend die, which can help improve the accuracy and consistency of the bends.

Flanged-based bend dies are often used when bending heavy-duty materials or when performing complex bends with a tight radius.

The flange provides additional support and stability, which can help prevent the tube/ tool from slipping or moving during the bending process.

Spindle mount bend dies, on the other hand, are the more popular style and mounted directly onto a spindle on the tube bending machine.

This type of mounting allows for quick and easy changes of the bend die, which can be beneficial when performing a variety of bends on different sizes or types of tubes.

Choosing the right bend die is crucial for achieving the desired bend. Here are some factors to consider:

The bend die plays a pivotal role in the tube bending process.

Understanding its function and how to choose the right one is essential for anyone involved in tube bending.

Remember, the success of your tube bending project largely depends on the quality of your bend die.

Both flanged-based and spindle mount bend dies have their advantages and are suited to different types of tube bending applications.

The choice between the two will depend on the specific requirements of your tube bending project.

If unsure, contact our expert Unison team – sales@unisonltd.com