Unison Ltd designs and builds complete production cells for a wide variety of tube bending and manufacturing applications. The cells are particularly suited to industries where production volumes are high, and production costs must be kept to an absolute minimum.

Typically based around Unison’s robust, industry leading all-electric Breeze tube bending machines, the cells can include other operations such as boring, pressing, punching, laser cutting, end forming, deburring, boxing and labelling. Unison are experts in integration and automation, incorporating add-ons like autoload and unload, robot welding, painting and assembly. Unison work cells are designed to keep labour costs down and efficiencies up.

Find out more about our tube bending automation – here

The customer in question is a leading global manufacturer and supplier of large, stamped metal and welded components, assemblies, and plastic parts for the automotive industry. The company is responsible for manufacturing boot hinge assemblies for several major automotive manufacturers.

The main component in these assemblies is a bent rectangular steel tube which was previously fabricated and supplied by a subcontractor. To reduce its reliance on outsourcing and ensure total control over accuracy, the customer decided to invest in an automated manufacturing cell to bring the production of boot lid hinge components entirely in-house.

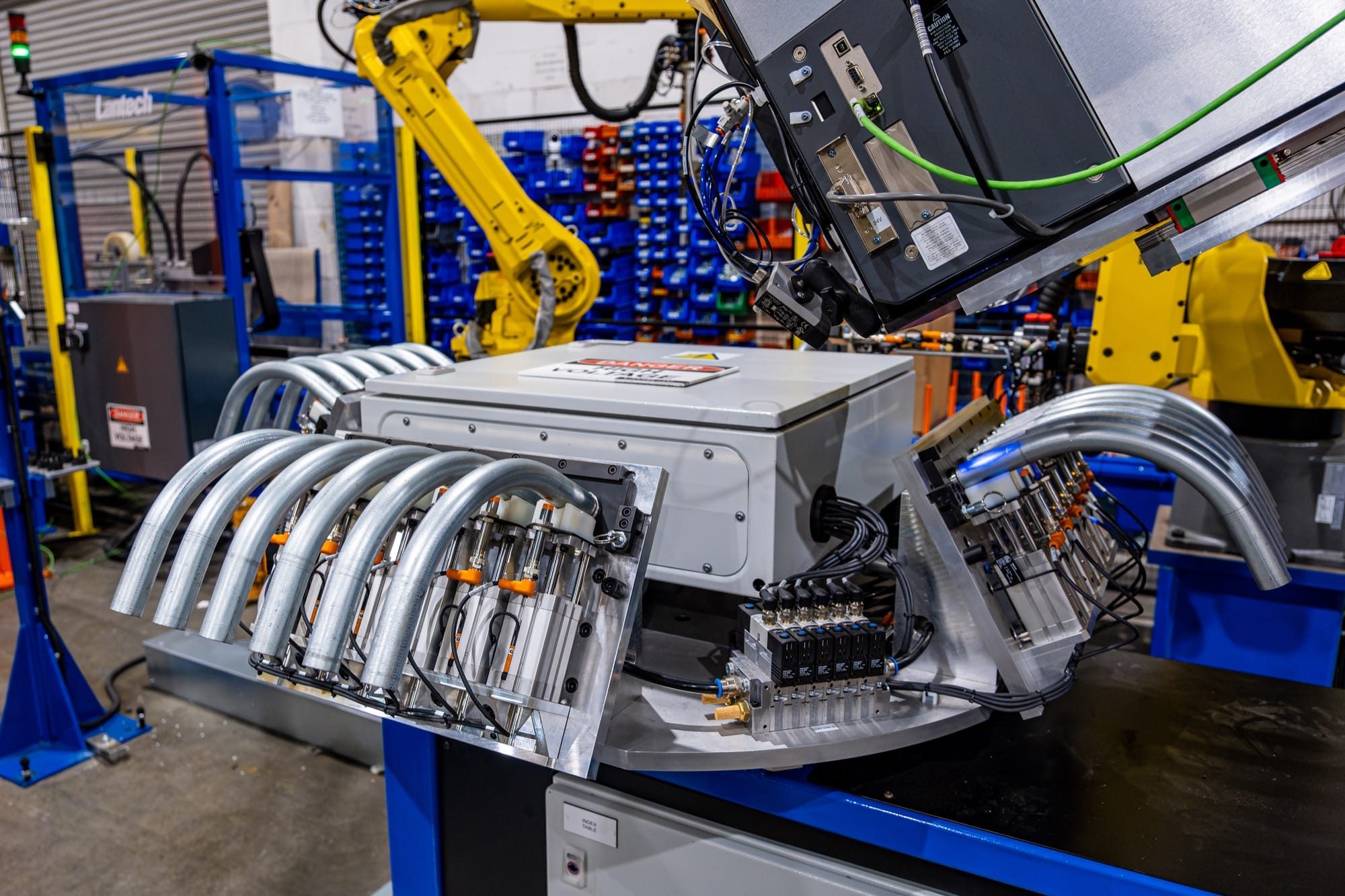

Unison’s solution involved two all-electric, servomotor-controlled 50 mm Breeze tube bending machines with multi-stack tooling heads. The bending machines are fed by two automatic hopper loaders which perform weld seam detection and datum the tube prior to bending. A robot then unloads the bent parts from each machine and presents them to a four-camera vision inspection system, to measure the parts and calculate corrections.

This closed-loop solution links with the bending machine’s motion control to ensure accuracy and repeatability. The bent components are then transferred by a further two robots into two CNC machining centres, where multiple holes of various sizes are drilled. Once complete, the components are robotically deburred and hung on transfer racks in pairs ready for delivery to the assembly station.

In a high-demand industry, working to ‘just-in-time’ supply principles, this customer has the ability to reliably produce hinge components in-house, with complete control of all aspects of boot lid assemblies.