There are several situations where it may be desirable to have a machine with the ability to mount multiple sets of bend tools. This is necessary if it is required to bend a part at several bend radii, if the part requires “bend on bend” (also known as compound) tooling or simply to reduce the number of physical tool changes. The machine can move the tube between each set (or “stack”) of tools. This is referred to as a “Multi Stack” machine.

Typically, a multi-stack machine will have a separate clamp and pressure die for each stack. If the bend formers have differing radii, the clamp and pressure die must be staggered in depth so that each tool set is able to close on the tube without being prevented from closing fully by the tools on another stack. So, you will have longer clamps and pressure dies on the smaller radii formers.

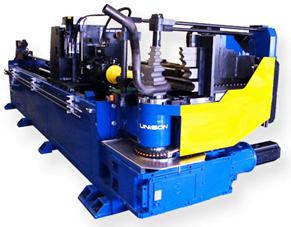

There are two types of Multi-Stack machine that must be considered. For machines with a maximum capacity less than or equal to 50mm OD the head is moved about a fixed DBB and Mandrel to achieve stack changes, known as head shifting. For machine with a maximum capacity greater than 50mm OD the head is fixed and the DBB and Mandrel are driven to achieve stack changes, known as fixed head multi- stack.

If you require to bend on both large and small radii within the same part then a Multi Radius machine is required. Similar to a Multi-Stack machine but this option includes pressure die vertical axis which allows the operator to move a single tool independently, following the stack. This avoids tool collisions associated with this type of bending.

When bending on a larger radius, the pressure die should move faster than if it was on a smaller radius in order to maintain constant pressure at the point of bending