We offer a wide choice of ancillary machines, each built to the same high standards as our Unison tube and pipe bending machines. Choose from high-quality end-forming machines, thread-rolling machines, coiling and de-coiling machines, coning and threading machines, special industrial washing machines, and fully automatic rising saws.

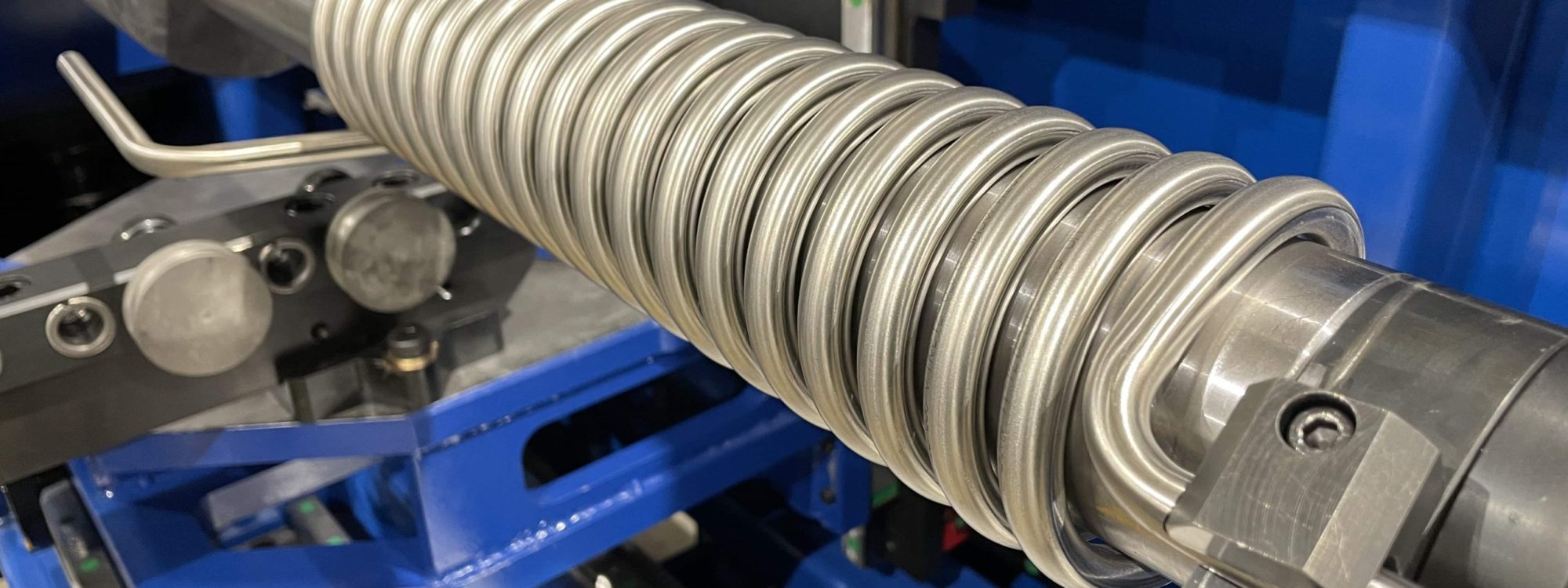

Tailored to each customer’s individual requirements, Unison all-electric CNC tube coiling machines are fully programmable in speed, profile and pitch. Unison coiling machines are used to produce the precise helical and pancake coils that are widely used in industries that require heat exchangers.

Offering seamless, precise coning and threading of tube ends, Unison coning and threading machines are available for medium, high and ultra-high-pressure connections. Industrial sectors include: hydraulics, lubricants, chemicals, oil & gas, and more.

Coning and threading for:

Individually built to specific customer needs, Unison CNC-controlled tube end-forming and beading machines are fully programmable and are used in sectors such as aerospace and oil & gas. Unison beading machines will add strength to the end of your tube or allow for hose attachments.

Unison tube washing and drying machines are used to ensure a spotless tube finish. Fitting seamlessly into automation systems, they can be found across a number of industries – particularly oil & gas. We have a large number of tube washing systems in daily operation around the globe. Choose from standard and inline conveyor solutions.

Unison flat bar forming machines are a favoured choice in stairlift railing production as well as other applications that require precise manipulation of flat bar materials, such as freeform and sculptured projects.

Turn Your CNC Waste into Profit with Mackma Briquetting Machines

Unison Ltd is now offering Mackma’s industry-leading briquetting machines – the smart way to handle CNC waste.

✔ Massively reduce volume for easier handling & transport

✔ Recover valuable internal liquids to cut waste costs

✔ Increase the commercial value of your shavings

Less waste, more efficiency, maximum return.

Let’s talk about how Mackma can streamline your operation – sales@unisonltd.com

Unison fully automatic rising saws feature a proven design for the most demanding of tube cutting applications. Standard features include hydraulic clamp, variable blade speed and dynamic cutting feed.