Design. Simulation. Manufacture. Integration. Commissioning…

At Unison, we don’t just build some of the world’s finest machine tools. Our automation division creates the work cell solutions that help manufacturers improve their productivity, efficiency and quality.

Working in highly regulated sectors, such as aerospace, automotive, food & beverage, nuclear, shipbuilding and oil & gas, we streamline production to enable leaner manufacturing.

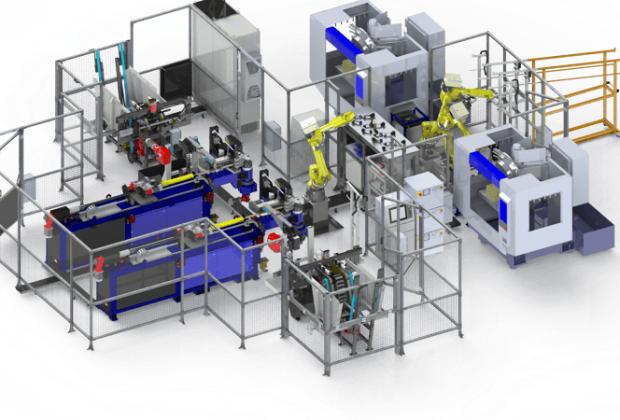

Depending on customer requirement, our fully automated work cells can include tube bending, pipe bending or wire forming solutions from Unison and Pneuform, fibre laser cutting technologies from Nukon Lasers UK, sophisticated jigs and fixtures, remote handling, robotised cells with transfer systems, tooling verification with remote diagnostics, and automated flowlines.

Always looking to future-proof technologies and deliver cost-efficiency, we work closely with customers to integrate the very latest advancements into our solutions. We can supply outputs to enable the collation of all data received from the manufacturing process to improve efficiency, productivity, quality and error prediction – optimising production.

From robotic cells to integrated production lines, our automation skills ensure customers receive cost savings and the best solution, to provide the highest level of automation.

Working alongside partners including Fanuc, ABB and Yaskawa, we provide the most appropriate technologies for our customers.