“D” of Bend: Centreline Radius (CLR) / Outside Diameter (OD)

Inside Diameter (ID): Outside Diameter – (Wall Thickness (WT) x 2)

Inside Radius: Centreline Radius (CLR) – (Outside Diameter (OD) / 2)

Outside Radius: Centreline Radius (CLR) + (Outside Diameter (OD) / 2)

Wall Factor (WF): Outside Diameter (OD) / Wall Thickness (WT)

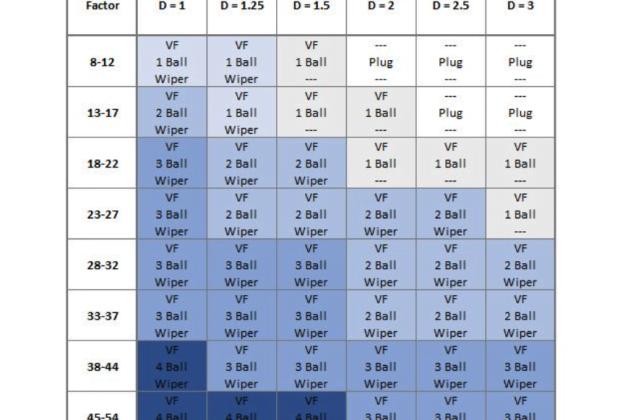

Difficulty Factor (DF): Wall Factor (WF) / “D” of Bend

Elongation (%): 0.50 x Outside Diameter x 100 / Centreline Radius (CLR)

Ovality (%): Max Outside Diameter (OD) – Min Outside Diameter (OD)

Pipe diameter refers to a nominal diameter- not actual. Pipe Schedule (see example, right) refers to the pipe’s wall thickness. The actual physical outside diameter is larger than it’s nominal OD.

The diameter of tubing on the other hand refers to the actual outside diameter. In other words, the actual physical OD of a tube is just the same as it’s nominal OD. For example: The actual outside diameter of 1/4” pipe is 0.54″ (13.716mm) – while ¼” tube has a true 0.25″ (6.35mm) outside diameter.